Installing Stolspeed Vortex Generators

Flight Testing

It’s essential to do proper flight testing before and after installing any VGs.

Record the results, don’t depend on memory! Not only will you be able to measure the differences, but you’ll learn a whole lot about the handling of your aircraft.

Preferably select a time when the weather is looking stable for a couple of days (ie- a large high pressure cell spreading over your area).

Do the first flight tests without VGs early one morning, install the VGs during the day, and flight test again with VGs early next morning when conditions will be consistent.

Instructions for the flight testing procedure are at Fight Testing.

CofG

It's also essential to establish that the CofG of your aircraft is correct before installing VGs.

And here we're talking about the actual loaded CofG as it is for flight right now, not just the empty aircraft, or calculations way back when it was built.

I keep running across aircraft owners seeking to use VGs to correct defects in handling which are really due to CofG problems - some due to additions over time - some obviously could never have passed a proper weight and balance at any time! (Auto engines need special attention...)

It's a trap, that most aircraft will fly fine under power even if the CofG is way out, but lose that power and reality bites - either can't get the nose up for a landing flare, or even worse, can't get the nose down in a stall .......

I know that very few aircraft owners ever do a weight and balance other than when it was built, but it sure is worthwhile exercise - now is a good time to do it!

..................................................................................................................................

Instructions for Installing Stolspeed VGs on your aircraft.

First it’ll be necessary to apply the special adhesive to the VGs.

This adhesive comes as a thin sheet in a sandwich between two backings. It’s a solvent-free, acrylic adhesive that won’t damage any paint surface. Once firmly pressed onto a clean surface it bonds really well, but still has flexibility. Sudden impacts will not knock it loose, but it can be peeled away by pulling steadily on the VG and sliding a razor blade under. To remove any remaining adhesive from the surface, just rub with your thumb and ‘roll’ it away in a little rubbery ball. It’s a perfect adhesive for this purpose!

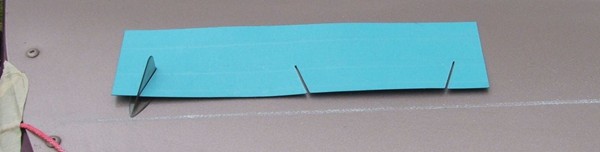

The sheets of adhesive now come already laser cut to the footprint of each VG. The laser often cuts through the backing of the adhesive as well, so to keep all the parts stable, place a couple of runs of tape across the backing (the printed side), as shown below. Best to use a tape with stronger adhesive, such as Gorilla™ instead of the masking tape in the photo.....

With the tip of a trimming knife, lift the front tip of the covering layer from a footprint.

Wipe the bases of all the VGs with methylated spirits, also called denatured alcohol or methyl hydrate.

Place a VG onto each footprint of the adhesive.

Holding each VG, rub the backing with a fingernail to press the adhesive firmly onto the VG and expel any air bubbles.

Hold each VG by the vertical wing and bend the adhesive backing away, starting at the tip of the VG.

This should lift the VG, with the adhesive stuck to it, from the backing.

The ideal temperature for applying this adhesive to the wing surface is between 60°F(15°C) and 100°F(38°C). If the temperature is below 50°F(10°C) the adhesive may not 'flow' properly for a good bond. If it's too cool use a heat gun or hair dryer to carefully warm both the wing surface and the VG.

If you need to remove any VGs, just pull on the fin while slipping a sharp blade under an edge.

If the adhesive is still fresh then you can remove any still stuck to the surface by just rubbing with your thumb to roll it into a ball.

If the adhesive is old and dried, then WD40 works fairly well.

If that still doesn't work then soak the adhesive with 3M Adhesive Remover and carefully scrape off with a single-sided razor blade.

Painting Stolspeed VGs

If your aircraft will be parked in the sun for much of the time, it's a good idea to paint the VGs. We have added the maximum UV protectant that is possible, but the thin section and transparency of these VGs will still allow some UV damage.

It's also worth painting the VGs for appearance, in that the transparent base will allow any dirt that migrates under the edges of the base to show through.

If you wish to paint your VGs, it is best done before they are installed on the wing. Even on a new aircraft it’s much better to first paint the wing without the VGs on, paint the VGs separately, then stick them on.

It's a bit tedious, but wipe the VGs with alcohol to clean off any release lubricant from the injection molding process.

It's very easy to paint the VGs on the adhesive sheet. Stick them in their spots on the adhesive sheet. Then attach the sheet to a block of wood to keep it from blowing away with spray blast. Spray them with several light mist coats, with a pause between each coat to allow the thinner to evaporate. Don't blast them with too much paint, just enough to give an even color.

Keep in mind that the VGs are flexible, so you won’t want a thick layer of brittle two-pack paint. Keep the paint layer thin, and without hardener if possible.

..................................................................................................................................................................

Determining the correct position for the Stolspeed VGs

The VGs need to be positioned such that they have the best ‘bite’ at the airflow when the wing is at the stall angle of attack. If they are too far aft they risk being buried in the thickening boundary layer and the start of separation, so they lose effectiveness at stall. Some have suggested that too far forward may slightly increase drag at cruise, but I have never been able to measure any loss of cruise speed. Better to be farther forward than too far aft. So, with the wing positioned at the stall angle of attack, the VGs should be slightly forward of the highest point of the airfoil.

Historically, the margin is considered to be 8-12% of wing chord back from the leading edge to the highest point of the VG, but I find that to be too far aft. There’s lots of talk around the hangar fliers of finding the ‘sweet spot’, but my experience doesn’t show any dramatic improvement at any one point. I suspect that some other manufacturers make a big deal of this in an effort to suggest a secret knowledge that only they possess........

From 8-10% I could detect no difference at all in stall performance, but would recommend not placing the VGs farther back than that, in case they become buried in the thickening boundary layer and suddenly loose effect at a high angle of attack, just when they are most needed. I have tested them at much farther forward positions and found the effectiveness unchanged. The vortexes once generated are very persistent and stream right back to the trailing edge of the wing. I couldn’t measure any change in drag at cruise speed with the VGs at any position.

Originally I recommended 7% set back, but now recommend 5% to be more in the middle of that range.

So I recommend placing the VGs with the front tips at 5% of chord aft of the leading edge We use the measurement to the tips of the VGs to mark the line on the wing because it's easier to place the VGs accurately to this line. If you try other positions and get significant results with your aircraft, please let us know so that others can benefit.

On a tapered wing, measure the chord at the base and near the tip and calculate 5% for each end. Run a string line between those points at each end.

There are specific measurements for the Zenith 701, 801, and 601 aircraft on their respective pages in the main menu.

For canard style aircraft place the VGs along a line at 50% of chord of the canard, at spacing of 30mm.

Preparing the wings.

Wash the wing thoroughly with detergent (not one of those automotive ‘wash-and wax’ products).

Measure the chord of the wing from the front of the leading edge to the aft edge of the ailerons or flaps. In the case of detached flaperons, measure to the aft edge of the main wing.

If the wing is tapered then measure both at the root and the tip.

Measure from a vertical line extended above the leading edge, with the aircraft at flying attitude.

A carpenter's level is convenient to establish this vertical.

Calculate 5% of each the those measurements.

Measuring from the leading edge again, mark those 5% points on masking tape at the ends of each wing.

Wipe a zone along that line with alcolhol.

Stretch a string line tightly over those marks, and secure it with masking tape at a couple of intermediate points.

Placing the VGs on the Wing

Starting 50mm (2”) from each wing tip:

Remove the backing from the adhesive on a VG.

Set the first VG in a notch of the 60mm template.

Carefully touch the very tip of the VG to the wing surface right behind the line.

Guided by the angle of the template, lightly set the base of the VG onto the wing surface.

Double check the alignment, and if correct, press the VG firmly onto the surface.

Rub each side of the base firmly with thumbnail or a popsicle stick to press out any air bubbles.

With the template secured by the first VG, use the remaining notches to set two more VGs in place.

Move the template so that the third notch is secured by the last VG already set, and set two more.

(Note: The present templates have four notches instead of the three shown here.)

Continue to place 15 VGs at the 60mm spacing = 900mm (3ft) from the wingtip.

(This closer spacing near the wingtip is to ensure that the tip does not stall first.)

Do the remaining portion of the wing with the 90mm spacing template.

120 VGs is enough to do 9.9 metres (32 ft) of wing at this spacing.

If a VG happens to land on a rivet or a seam, displace it just enough to miss the obstacle, then continue the regular spacing.

Placing VGs on the Horizontal Stabilizer

Stretch a line on the underside of the horizontal stabilizer, 100mm (4”) in front of the gap between the stab and the elevator.

Using the 30mm spacing template, set a row of VGs with the front tips along that line, starting from the outside.

If the surface of the horizontal stabilizer is flat, the curved base of the VG will contact only at he tip and the heel. Rub the VG on a piece of sandpaper laid on a flat surface to adjust. Don't try to completely flatten the base - just make flat areas at the tip and heel, the adhesive will do the rest.

Placing VGs on the Vertical Fin

Stretch a line on the vertical fin 100mm (4") in front of the gap between the fin and the rudder.

Using 30mm spacing template, set a row of VGs with front tips along that line.

The hinge line will likely be swept back, so orient the template each time so that all the VGs are oriented with the front tips about 5º upward to the horizontal, instead of alternating. This way all the VGs will be near the optimum 15º when the aircraft is nose high at landing and take-off when the rudder effect is most needed.

Of course, do both sides of the fin.

For a Wing with a swept-back leading edge

Since the VGs need to be oriented with respect to the airflow rather than the leading edge, a slightly different procedure is needed with a swept-back leading edge. The VGs are effective at angles from 10º to 20º, so setting them at 15º allows for best margin of variable airflow. So we need to orient the template at right angles to the expected airflow.

Snap a chalk line 5% back from the leading edge as before.

Place the VG with front tip at the line, but orient the template at 90degrees to the airflow rather than along the string line.

..................................................................................................................................................................

Note for aircraft with slats:

The easiest and tidiest way to remove the slat brackets, is just to cut them off about 12mm from the skin, along the profile of the leading edge. Then they look like miniature stall fences, and you don't have to fill the holes in the skin.

..................................................................................................................................................................

Certified Aircraft

Please note that Stolspeed VGs are not STC approved for certified aircraft.

............................................................................................................

Note – Be very careful when refuelling wing tanks –

Polycarbonate is very tough stuff, but fuel destroys it!

............................................................................................................